Vacuum Chlorinator

We are offering our valued clients an impeccable range of Vacuum Chlorinator. Under this range, we offer Vacuum Operated Floor Mounting Chlorinator, Vacuum Operated Pedestal Mounted Chlorinator, Chlorine Monitor (Semi Automatic), Chlorine Injector, Chlorine Injector System and Vacuum Regulator. Developed with latest technology, these products are effective for water purification in water treatment & testing needs of commercial, municipal, breweries, swimming pools, urban & rural water supply schemes and private sectors.

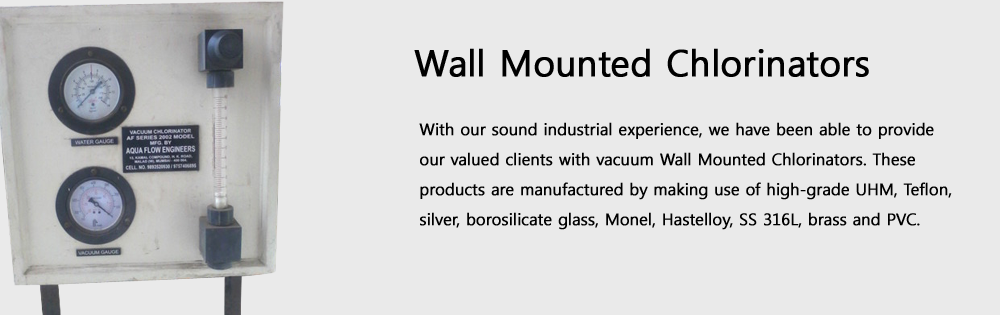

Vacuum Operated Pedestal Mounted Chlorinator

We bring forth the best Vacuum Operated Pedestal Mounted Chlorinator for our valued clients. Designed to impeccability, these products conform to the defined parameters of the industry. Furthermore, to cater to the divergent demands of the clients, we offer these products in 2kg/hr, 5kg/hr and 10kg/hr. The AF SERIES 2002 model of these chlorinators require low maintenance and provide consistent performance. These chlorinators are provided with stand mounted or remote injector and molded fiber glass panel.

We bring forth the best Vacuum Operated Pedestal Mounted Chlorinator for our valued clients. Designed to impeccability, these products conform to the defined parameters of the industry. Furthermore, to cater to the divergent demands of the clients, we offer these products in 2kg/hr, 5kg/hr and 10kg/hr. The AF SERIES 2002 model of these chlorinators require low maintenance and provide consistent performance. These chlorinators are provided with stand mounted or remote injector and molded fiber glass panel.

Design :

• Vacuum regulator mounted on valve (IS3224) above the liquid trap cum filter to separate foreign materials and liquid carried by chlorine gas can be mounted on wall

• Chlorine pressure gauge present for displaying cylinder/ tonner chlorine pressure is situated on body

• Vacuum regulator connected by means of string PVC/Nylon braided pipe to chlorinator panel

• Water gauge and Vacuum gauge on front panel to display vacuum created in injector and power water pressure

• Differential regulator to absorb vacuum variation and constant vacuum passing to Chlorine flow meter is present between injector and control valve

| Materials : • Fiber Glass • UHMW • PVC • Hast-alloy • SS316 • PTFE (Teflon) • Viton Robber • CS 106 grade • Sch. 40 |

Capacity Ranges Available : • 2kg/hr • 5kg/hr • 10kg/hr |

Chlorinator Accessories

Offering a Chlorinator Accessories. We conceptualize and develop these products while taking into consideration prevailing markets demands and industry laid parameters. Manufactured using high-grade basic material and components, these products are suitable for Chlorinator Accessories. These products are specifically designed to create the Chlorinator Accessories.

Offering a Chlorinator Accessories. We conceptualize and develop these products while taking into consideration prevailing markets demands and industry laid parameters. Manufactured using high-grade basic material and components, these products are suitable for Chlorinator Accessories. These products are specifically designed to create the Chlorinator Accessories.

Features:

• Non-corrosive

• Low operational cost

• Durable.

Chlorine Injector System

We hold all the aces in designing and developing the best Chlorine Injector System. The entire production process of these systems is carried out under the supervision of our team members. They precisely develop these systems in line with the defined parameters of the industry. Owing to their precision engineering, these products are widely used for dissolving chlorine into water. Furthermore, to satisfy divergent demands of the clients, we offer these systems in different specifications.

We hold all the aces in designing and developing the best Chlorine Injector System. The entire production process of these systems is carried out under the supervision of our team members. They precisely develop these systems in line with the defined parameters of the industry. Owing to their precision engineering, these products are widely used for dissolving chlorine into water. Furthermore, to satisfy divergent demands of the clients, we offer these systems in different specifications.

Features:

• Low maintenance

• Reliable

• Durable

• High performance

• Easy operation

• Robust construction

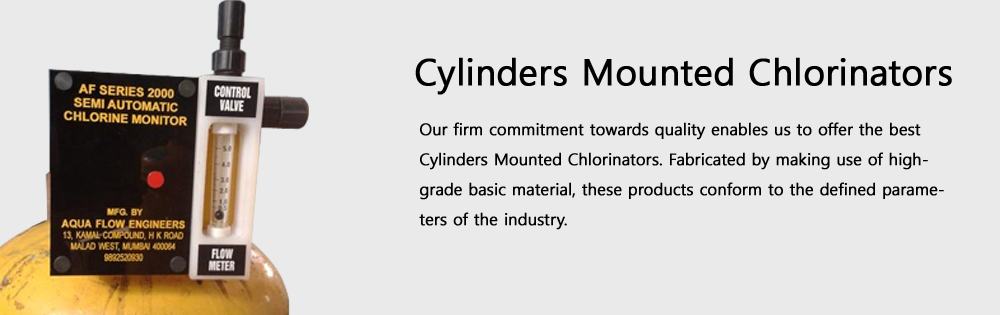

Semi Automatic Chlorine Monitor

With the support of our team, we have been able to provide our valued clients with the best Semi Automatic Chlorine Monitor . Our team develops these products keeping in mind industry laid parameters and prevailing market demands. They manufacture these products by making use of high-grade basic material, procured from the established vendors of the industry. Furthermore, these are offered in Af Series Dcm AF SERIES 2000 model that are suitable for water purification applications in water treatments plant and swimming pool applications. With no danger of chlorine leakage, these products are suitable for mounting on 100kg chlorine cylinder. Furthermore, these monitors can be connected with remote injector directly on wall or pump outlet. These products are available in three capacity ranges such as 2kg/hr, 5kg/hr and 10kg/hr.

With the support of our team, we have been able to provide our valued clients with the best Semi Automatic Chlorine Monitor . Our team develops these products keeping in mind industry laid parameters and prevailing market demands. They manufacture these products by making use of high-grade basic material, procured from the established vendors of the industry. Furthermore, these are offered in Af Series Dcm AF SERIES 2000 model that are suitable for water purification applications in water treatments plant and swimming pool applications. With no danger of chlorine leakage, these products are suitable for mounting on 100kg chlorine cylinder. Furthermore, these monitors can be connected with remote injector directly on wall or pump outlet. These products are available in three capacity ranges such as 2kg/hr, 5kg/hr and 10kg/hr.

Operation:

• These products can be operated on vacuum made by water pressure with booster pump or other power line in the injector nozzle

• The offered products start operating when vacuum in injector goes thorough LDPE vacuum tube for monitoring mounted on chlorine cylinder valve with self attached yoke clamp

• Created vacuum can be controlled with the help of top mounted valve on chlorine flow meter while measuring chlorine flow/hr

• These products are provided with inlet valve which shuts off on its own in case water pressure gets interrupted and vacuum loss occurs, thereby ensuring no leakage even if the chlorine cylinder valve gets opened

• Water pressure required by injector for creating vacuum: 2.5kg/cm2 (gravity dosing considered) when water supply is restored and chlorine dosing starts at previously stated levels

| Material: • PVC • UHMW • SS316 • PTFE (Teflon) • Hast-alloy • Viton rubber |

Capacities Available: • 2kg/hr • 5kg/hr • 10kg/hr |

Vacuum Regulator

Keeping in sync with the ever-changing demands of the customers, we have been able to provide the customers with a comprehensive assortment of Vacuum Regulators. Developed at par with the global quality standards, the range assures safe withdrawal of chlorine from cylinders. Available in variable vacuum principle capacities up to 75 kg/hr., the range is acknowledged for the following attributes:

Keeping in sync with the ever-changing demands of the customers, we have been able to provide the customers with a comprehensive assortment of Vacuum Regulators. Developed at par with the global quality standards, the range assures safe withdrawal of chlorine from cylinders. Available in variable vacuum principle capacities up to 75 kg/hr., the range is acknowledged for the following attributes:

Features:

• Easy operation

• Low maintenance

• Robust construction

• Reliable performance

Chlorine Injector

We are providing our valued clients with the best Chlorine Injector. Designed to perfection, these injectors are in compliance with the defined parameters of the industry. Therefore, these injectors in provide excellent performance in waster water treatment plants and other areas requiring water disinfection. These products are specifically designed to create the desired vacuum.

We are providing our valued clients with the best Chlorine Injector. Designed to perfection, these injectors are in compliance with the defined parameters of the industry. Therefore, these injectors in provide excellent performance in waster water treatment plants and other areas requiring water disinfection. These products are specifically designed to create the desired vacuum.

Features:

• Corrosion resistant

• Advanced fail-safe mechanism

• Easy to install & maintain

Operation and construction:

• Vacuum is created by power water pressure to nozzle

• Chlorine extracted from monitor is mixed with water and that solution is carried to point of application

• Provided double non return valve at injector bottom prevent water back flow to monitor after shut-off. If it still passes to NRV then draining through valve can be done

• Injector inlet mounted gauge effectively measure power water pressure

Mounting options of these injectors are also available as mentioned below:

• Wall mounting with brackets

• Directly on pump outlet